In agriculture applications such as greenhouses, to achieve consistent crop quality and yield it is important to consider not only the soil conditions but a whole range of other factors including the irrigation and surrounding environment. The diverse range of parameters involved mean that systems which monitor and/or control only soil condition, environment or irrigation do not enable the farm to take advantage of the full potential that automation can bring.

IoTPortal offers an effective solution with its wide range of sensors/actuators covering all areas of the grow environment, as well as automation features to make more efficient use of staff and the ability to scale effortlessly to cover any size of farm.

Ineffective monitoring of the entire set of growing conditions can lead to lower crop yield and poor quality. Soil condition alone, without nutrient/watering and air conditions, is not sufficient to ensure good results. Manual monitoring is labour-intensive especially over large farms, leading to excessive intervals between measurements.

Effective monitoring of the growing conditions is not enough to ensure good yields. Manual intervention to restore optimal conditions is labour intensive and requires staff to be on-site. Delays in responding causes crop health to suffer.

To be profitable and to produce sufficient volumes to satisfy demand, farms often need to scale up with multiple greenhouses spread over a large area. Limitations in the range and scale of monitoring and automation systems means that they cannot grow with the farm.

Automation can help reduce staff workload and improve efficiency. However, configuring and operating them is often outwith the key skill set of staff. Automation is not used to its full potential and the farm becomes dependent on the external automation provider for even minor changes in set-up.

Farms need to continually optimize and refine grow recipes but are unable to do so unless they can capture data over the entire grow cycle for analysis. Hidden costs such as energy and water usage can impact profitability even if the farm has been able to optimise the crop yields and volumes.

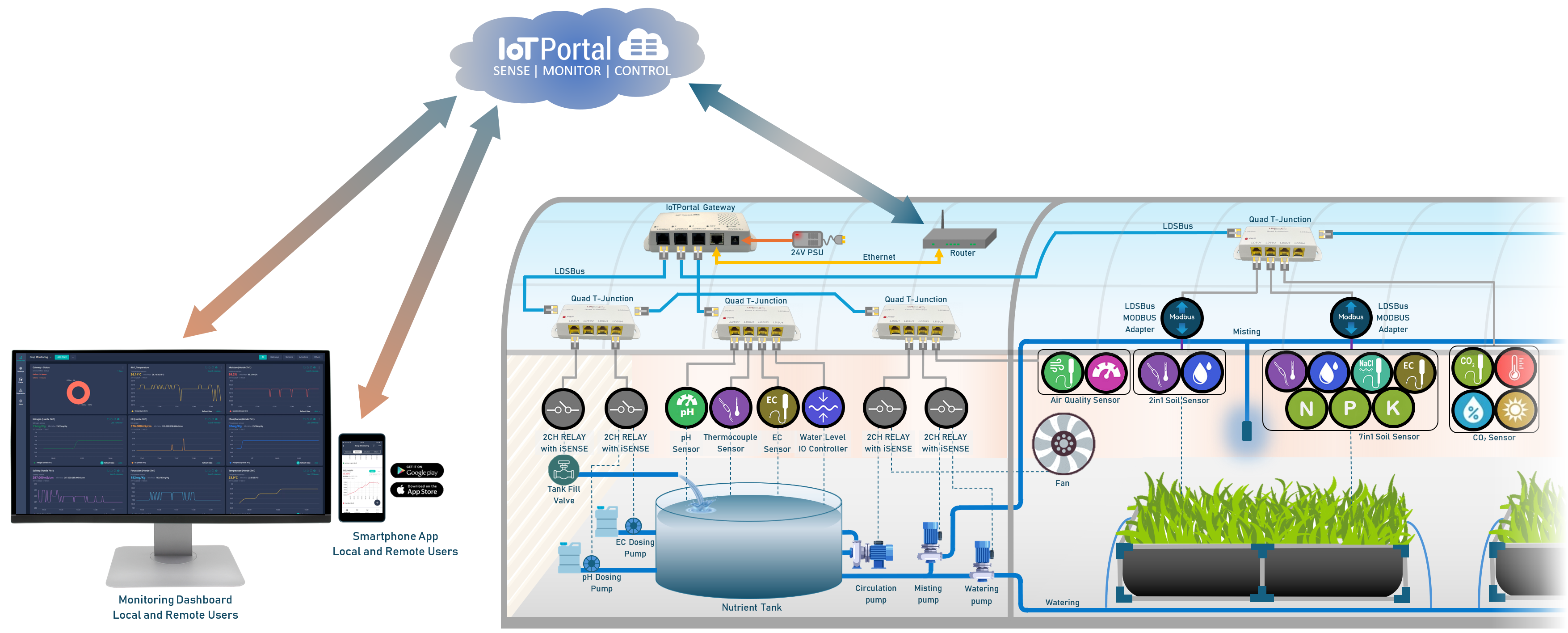

In this example of a greenhouse, a combination of BRT Systems sensors and actuators as well as 3rd party soil sensors monitor all key aspects of the ecosystem, including soil, surrounding environment and irrigation.

IoTPortal offers continuous real-time monitoring of a large network of sensors. BRT Systems have a wide range of sensors for nutrient tanks, environment sensing, water consumption, energy usage as well as connectivity of external Modbus sensors for soil. IoTPortal can alert staff via Email, SMS and Push Notifications when parameters deviate beyond set limits.

The IoTPortal Events feature allows it to respond automatically to control devices via output actuators to maintain optimal conditions according to the recipe for the entire grow cycle beginning from when young plants are first planted into the grow beds, right up to harvest.

A single IoTPortal gateway can support between 1 to 320 sensor/actuator channels with three 200m long LDSBus connections which also provide power to all devices. Additional gateways may be added to meet the required scale. The farm can quickly and easily adapt to volume demands and different crop types.

With no programming required, farmers can easily set up and modify the automation environment with their grow recipes. This reduces training and outsourcing costs while overcoming the anxiety and resistance that staff may have to automation.

The IoTPortal stores all the sensor and actuator data for visualisation and analysis but sensitive data such as input costs, and output crop yield by weight, electricity and water costs are kept within the farmers’ systems. For a complete analysis, the IoTPortal provides integration with Microsoft PowerBI™ and Microsoft Fabric™ and for simpler analysis connections to GoogleDocs and Microsoft Excel are provided.

IoTPortal helps achieve more consistent yields and crop quality in Vertical Farming applications

BRT Systems Pte Ltd (BRTSys) provides cutting-edge IoT solutions that drive operational excellence and deliver significant cost-value benefits with two families of solutions: IoTPortal and PanL

Beware of Fake, Phishing and Spoofing Emails

Do not respond to these emails or communicate with the sender, and do not provide the sender with any personal or financial information. In addition, avoid clicking on links included in the emails, or the attachments as it may result in malware, or a virus being loaded on the recipient’s computer.

If you receive email solicitations from anyone posing as the company, its group affiliates or company officers that appears even remotely suspicious, please contact us immediately.